A Comprehensive Overview to the Kinds of Ceramic Coating on the Market

Ceramic layers have actually emerged as a crucial service across numerous markets due to their distinct buildings and applications. As we explore the distinct characteristics and applications of these finishes, the effects for efficiency and longevity end up being increasingly apparent, raising inquiries concerning which kind could best suit your needs.

Recognizing Ceramic Coatings

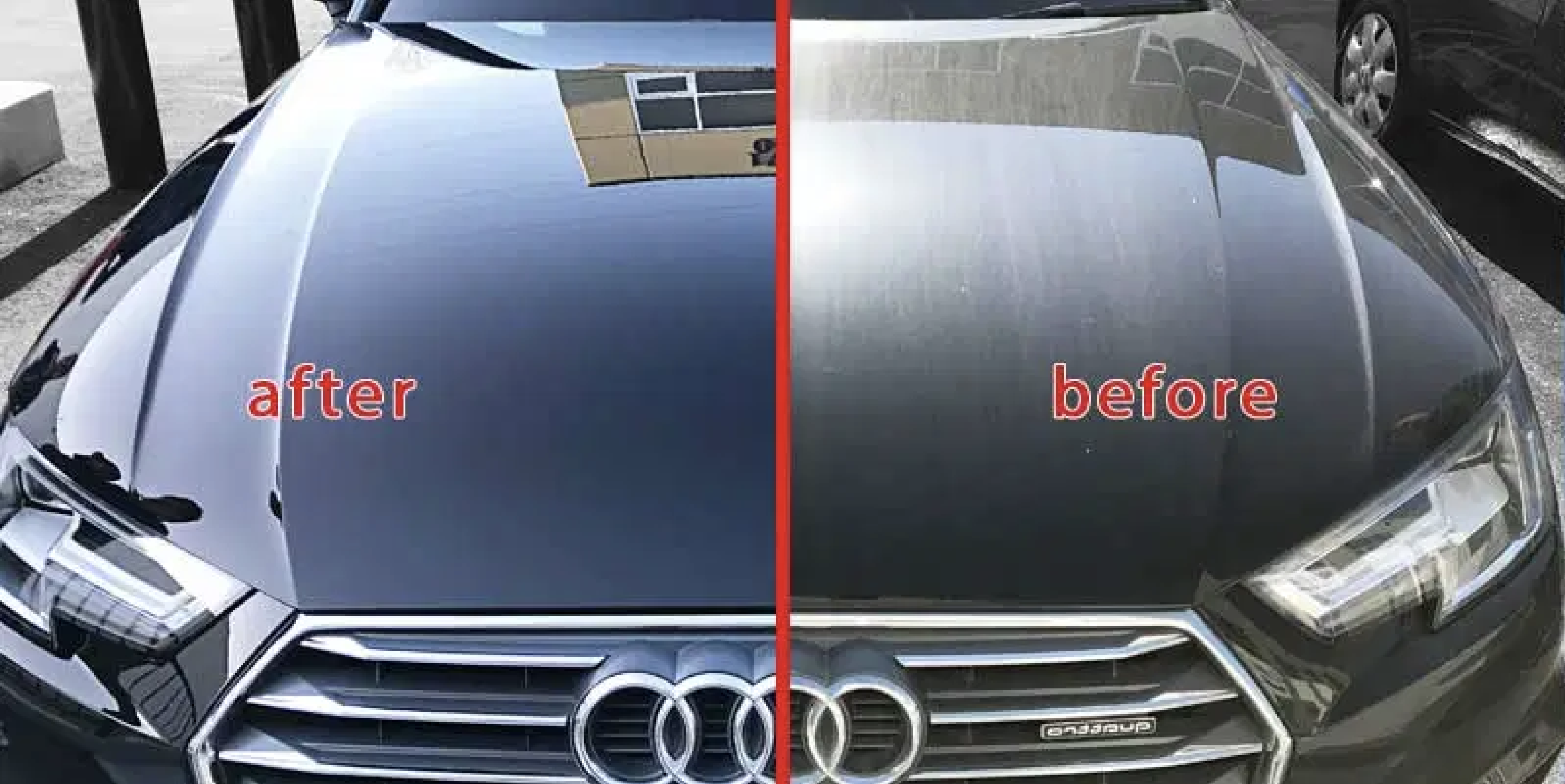

Ceramic finishings are sophisticated safety remedies that have obtained popularity in different industries, especially in automobile and aerospace applications. These layers include a liquid polymer that, when healed, forms a resilient, hydrophobic layer on the surface area of the substratum. This layer offers boosted resistance to environmental pollutants, UV radiation, and chemical exposure, thereby expanding the life and aesthetic appeal of the underlying product.

The fundamental component of ceramic coatings is silica, which adds to their firmness and durability. The application procedure generally entails surface area preparation, application of the coating, and curing, which can be attained via warmth or UV light. Once healed, ceramic coatings exhibit remarkable bonding residential properties, enabling them to stick highly to a range of surfaces, consisting of metals, plastics, and glass.

In addition to their protective attributes, ceramic finishes additionally provide convenience of maintenance. Their hydrophobic nature minimizes the adherence of dirt and grime, making cleaning easier and much less frequent. In general, the fostering of ceramic finishes stands for a significant advancement in surface security technology, giving both functional and aesthetic benefits across multiple fields.

Types of Ceramic Coatings

Numerous sorts of ceramic finishes are readily available, each developed to fulfill certain efficiency requirements and applications - scratch repair sarasota. One of the most common kinds consist of:

Silica-based Coatings: These coatings mostly include silicon dioxide and are recognized for their resilience and chemical resistance. They are extensively used in automobile and industrial applications.

Titanium Dioxide Coatings: Distinguished for their photocatalytic properties, titanium dioxide finishes are often used in atmospheres where self-cleaning and antifungal residential or commercial properties are preferable, such as in structure products and automotive surfaces.

Zirconia Coatings: Identified by their high-temperature stability and thermal resistance, zirconia coverings are made use of in applications such as wind turbine engines and high-performance automobile elements.

Alumina Coatings: Showing excellent solidity and thermal security, alumina coatings are regularly used in wear-resistant applications, consisting of cutting devices and commercial equipment. - Auto Detailing

Crossbreed Coatings: Combining the residential or commercial properties of various materials, hybrid finishes use boosted efficiency features, making them ideal for one-of-a-kind and requiring applications.

Each kind of ceramic layer offers distinctive objectives, enabling customers to pick one of the most ideal option based on specific environmental problems and performance needs.

Advantages of Ceramic Coatings

Ceramic coatings, in certain, deal numerous benefits that make them progressively popular amongst suppliers and customers alike. These coverings are resistant to scrapes, chemicals, and UV rays, guaranteeing that the underlying surface area continues to be safeguarded over time.

In enhancement to durability, ceramic coatings provide exceptional hydrophobic homes, enabling easy cleansing and upkeep. This water-repellent nature decreases the adherence of dirt, gunk, and other impurities, which can lengthen the aesthetic appeal and functionality of the surface area. Ceramic coatings can considerably enhance thermal resistance, making them excellent see post for applications that sustain high temperatures.

Application Process

When using ceramic finishes, a precise method is essential to achieve optimal results. A tidy surface guarantees appropriate adhesion of the coating.

Once the surface is prepped, the following step is to apply the ceramic coating. This can be done making use of an applicator pad or a microfiber fabric, guaranteeing even insurance coverage. It is important to operate in small areas to maintain control and avoid premature curing. The layer needs to be applied in thin layers, as thicker applications can bring about irregular coatings.

After application, the finishing needs a specific curing time, typically ranging from a couple of hours to a full day, depending on the product. Adhering to these actions faithfully will make the most of the effectiveness and durability of the ceramic covering, offering a long lasting safety layer for the surface area.

Maintenance and Longevity

To make sure the long life and effectiveness of a ceramic finishing, normal maintenance is vital. Ceramic coatings, recognized for their durability and protective top qualities, require certain treatment routines to optimize their lifespan and performance. The primary step in upkeep entails regular washing with pH-neutral soap, preventing extreme chemicals that can deteriorate the finish. It is advisable to clean the lorry on a regular basis, ideally every 2 weeks, to stop the accumulation of impurities that can compromise the finish's stability.

Along with regular cleaning, routine inspections are critical. Try to find indicators of wear or damage, such as hydrophobic properties lessening or surface area imperfections. If necessary, a light gloss might be used to rejuvenate the covering without stripping it away.

Furthermore, the application of a booster spray can improve the coating's hydrophobic results and restore its gloss. This is particularly helpful for finishes that have actually remained in use for an extensive period. Ultimately, by sticking to these upkeep techniques, one can dramatically extend the life of a ceramic coating, guaranteeing that it proceeds to give optimum defense versus environmental factors and preserve the visual appeal of the car.

Final thought